Discover the Long-lasting Efficiency of Bronze Bushing for Industrial Applications

Wiki Article

Effectively Reduce Rubbing With High-Quality Bearing Bushings

One efficient means to accomplish this is via the use of top quality bearing bushings. In this conversation, we will certainly check out the significance of bearing bushings, the variables that impact friction in equipment, the advantages of using top quality bushings, and provide sensible ideas for choosing and mounting them. Let us embark on this trip to discover just how premium bearing bushings can efficiently lower friction and boost the performance of equipment.Value of Bearing Bushings

Bearing bushings play a critical duty in making sure the reliable and smooth operation of numerous mechanical systems. These small elements are designed to minimize rubbing and offer assistance for rotating or moving shafts. By working as a barrier in between moving components, birthing bushings help to decrease damage, expand the life expectancy of machinery, and enhance total performance.Among the vital functions of birthing bushings is to lower friction. When two relocating surface areas come into get in touch with, rubbing is generated, which can trigger wear, warm, and power loss. Bearing bushings are made from products with reduced coefficients of rubbing, such as bronze or self-lubricating polymers, which help to lessen this rubbing. This enables smoother and much more effective activity, reducing the strain on the machinery and enhancing its general power performance.

In addition to reducing friction, bearing bushings also offer support and stability to rotating or gliding shafts. They help to preserve appropriate placement and protect against too much activity or resonance, making certain that the mechanical system runs efficiently and accurately. Without the assistance of birthing bushings, the shafts might be susceptible to misalignment, causing boosted friction, wear, and prospective damage to the whole system.

Elements Affecting Friction in Equipment

As the smooth operation and durability of machinery depend greatly on lowering rubbing, it is essential to comprehend the different aspects that contribute to friction in equipment. There are several variables that impact friction in machinery.The first aspect is surface roughness. When the surface areas of two parts are rough, the call area boosts, resulting in higher rubbing. Polishing or oiling the surface areas can decrease rubbing by smoothing out the roughness.

The 2nd factor is the kind and top quality of lubrication. Appropriate lubrication creates a thin movie in between the moving surface areas, reducing direct call and reducing rubbing. The thickness and temperature of the lube additionally play a considerable duty in friction reduction.

The 3rd variable is the load or pressure related to the surface areas. Higher tons boost the surface area contact area and the rubbing pressure. Proper load circulation and harmonizing are very important to avoid too much friction.

In addition, the speed of the relocating parts, the product residential properties of the components, and the environmental conditions, such as temperature level and moisture, can additionally affect friction in machinery.

Benefits of Utilizing High-Quality Bearing Bushings

Utilizing high-quality bearing bushings provides various benefits in regards to improving equipment efficiency and long life. These advantages make spending in high-grade bearing bushings a wise choice for organizations operating hefty equipment.Among the key advantages of making use of high-quality bearing bushings is reduced friction. Rubbing is a significant variable that can bring about tear and put on on equipment parts, causing lowered efficiency and boosted maintenance expenses. Top quality bearing bushings are developed to minimize friction, enabling smoother procedure and minimizing the danger of damage to equipment components.

Furthermore, premium bearing bushings contribute to improved performance. By minimizing friction, these bushings help to maximize power transfer within the machinery, causing raised efficiency and decreased energy consumption. This not just enhances overall performance yet likewise aids to reduce functional costs over time.

Kinds Of High-Quality Bearing Bushings

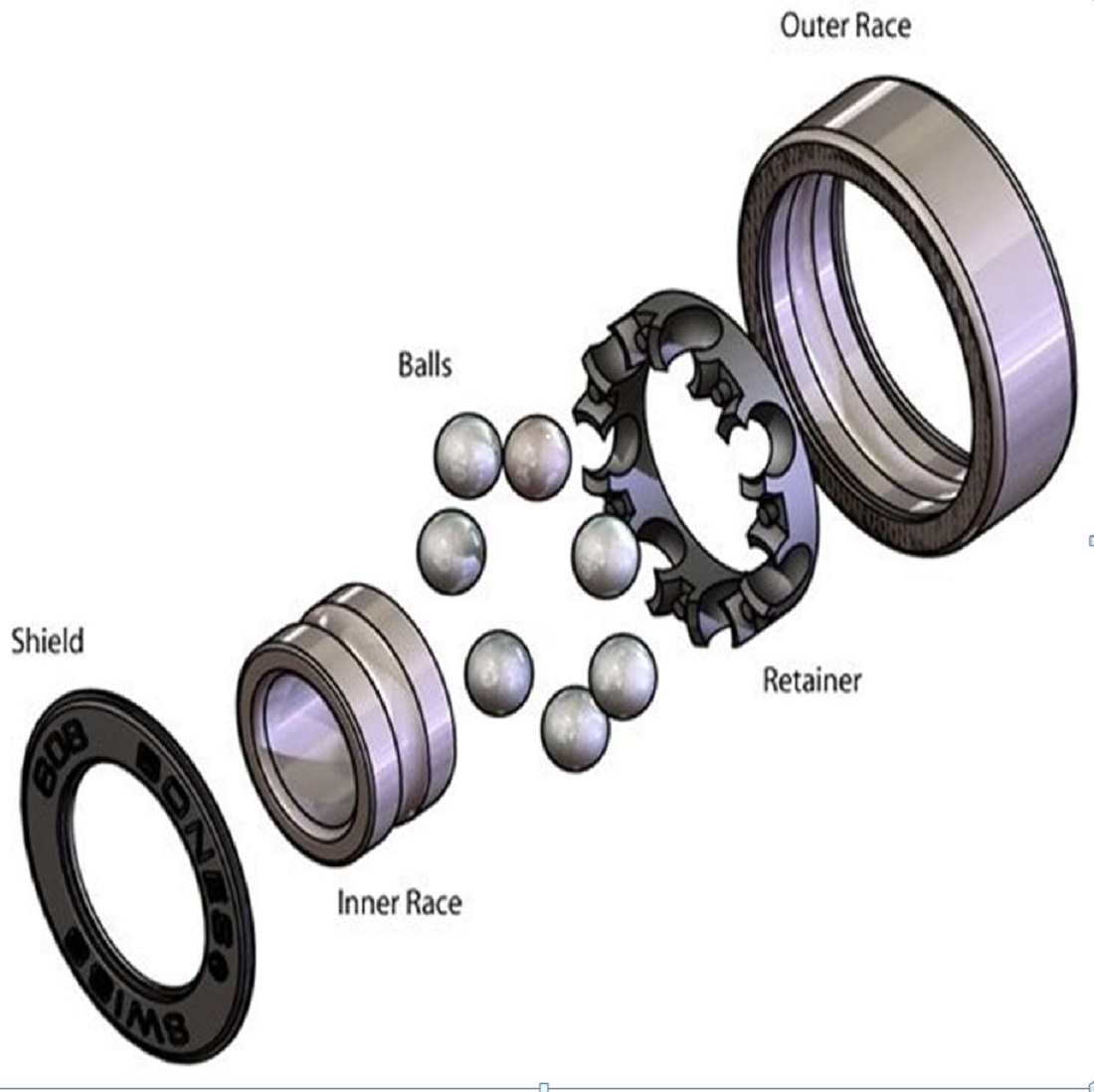

There are several distinct selections of top notch bearing bushings readily available on the market. One prominent kind is the plain bearing bushing, also recognized as a sleeve bearing or journal bearing.One more kind is the rolling component bearing bushing, which is typically made use of in you could try here applications where higher rates and heavier lots are involved. This sort of bushing incorporates moving elements such as spheres or rollers, which enable smoother and extra efficient turning.

Self-lubricating bearing bushings are also commonly made use of, especially in applications where upkeep is pricey or challenging. These bushings are constructed from products such as Nylon, ptfe, or graphite and have built-in lubrication residential properties, eliminating the requirement for outside lubrication.

Tips for Deciding On and Installing Bearing Bushings

One important factor to consider when choosing and installing high-grade bearing bushings is to very carefully assess the details demands and applications, building on the expertise of the distinct kinds discussed in the previous subtopic. To begin directory with, it is vital to comprehend the lots capability and rate requirements of the application. This will assist in determining the proper product and style of the bearing bushing to ensure ideal performance and durability.Another aspect to consider is the operating atmosphere. Whether the bushings will be revealed to high temperatures, destructive chemicals, or extreme climate condition, it is vital to pick a material that can stand up to such problems without compromising its efficiency.

In addition, the installation process plays a substantial role in the efficiency of the bearing bushings. It is necessary to guarantee appropriate placement and fitment to stop any type of unneeded stress and anxiety or misalignment that might cause early failing. bronze bushing. Lubrication is also important to lower rubbing and wear between the bushing and the turning shaft

Finally, normal examination and upkeep are necessary to guarantee the continued efficiency of the bearing bushings. This consists of you can find out more monitoring for indications of wear, checking lubrication degrees, and addressing any issues quickly.

Final Thought

In final thought, top notch bearing bushings play a critical duty in lowering rubbing in equipment. By selecting and setting up the ideal kind of bearing bushings, the effectiveness and performance of the machinery can be greatly improved. Factors such as worldly top quality, lubrication, and appropriate installation methods all add to decreasing friction and making best use of the life expectancy of the machinery. For that reason, it is necessary to buy top quality bearing bushings to achieve optimum efficiency and durability.In this conversation, we will check out the significance of birthing bushings, the aspects that affect rubbing in machinery, the advantages of using high-grade bushings, and supply practical pointers for choosing and mounting them. Let us get started on this journey to find how top notch bearing bushings can efficiently lower friction and improve the efficiency of machinery.

Birthing bushings are made from materials with low coefficients of rubbing, such as bronze or self-lubricating polymers, which help to decrease this friction. Top notch bearing bushings are designed to reduce rubbing, allowing for smoother operation and lowering the risk of damages to equipment parts.

Report this wiki page